The control system

Tessil Controll System helps customers handle the logistics. Its vast experience has lead to the improvement of the control systems and the performance of its personnel, resolving many issues related to every process and type of fabric: unbleached fabric, fabric ready for dying, finished fabric and jersey. In every phase, machinery, procedures and personnel, contribute to guarantee full quality.

Arrival and preparation

1. The bolts are collected daily by our forwarding agents from companies that have chosen Tessil Controll System and their suppliers.

2. On the arrival of the truck, the single bolts are divided according to the client and “cleaned” from the packaging as well as any eventual impurities, which has deposited during transportation.

Colour inspection

1. A piece of fabric is removed for an initial colour inspection and for colour variations from the salvage to the centre.

2. The fabric which is taken from the bolt is compared to the sample given by the client to Tessil Controll System and approved.

3. In case of slight differences in the colour tones (nuances), continuity cards are created, which the manufacturers can use to create uniform batches.

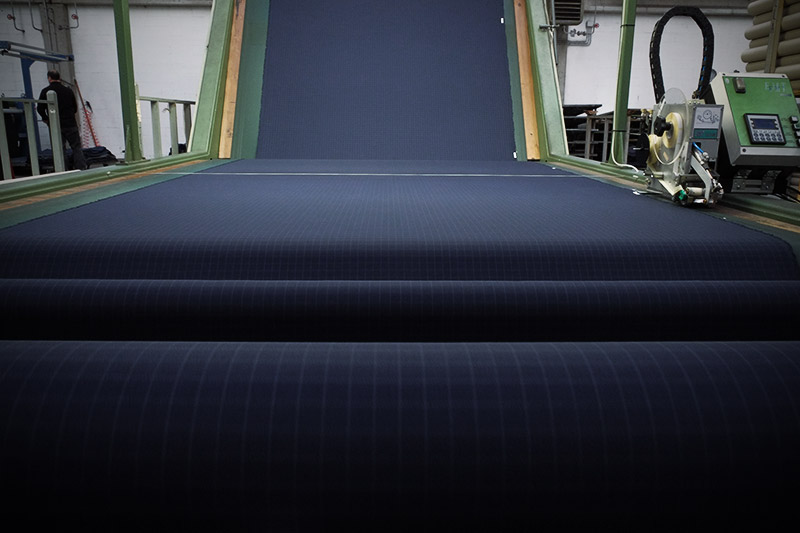

Fault inspection

The whole lot then passes to the actual control affected by specialised personnel. The experience of these professional figures, allows the immediate identification of various types of defects, like:

- holes

- knots

- mending

- impurities

- patches or strikethrough

- defective threads

Other parameters are verified, such as:

- weight

- length

- height

- texture and appearance

- grain lines

- regularity in checks

- regularity in colour

- beginning – finish of the bolt (head – tail)

- resistance of colour during manual handling

The dimensional test on the stability of the bolt can be personalized and conducted according to European regulations.

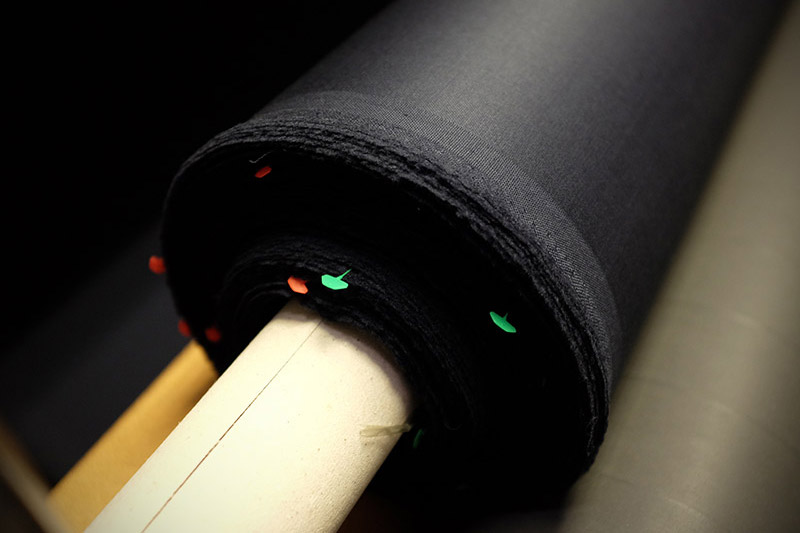

All defects are immediately identified by various methods, at the client’s request (stickers, thread, chalk, indelible chalk). Besides a printed and digital Inspection Report is produced depicting all the imperfections, making it easy to identify, allowing the producer to take any necessary decisions on the fabric.

Mending

One of the main elements that distinguish Tessil Controll System is the complete service offered. The company offers its clients, under request, the possibility of eliminating defects in the fabric within their own premises. Mending is done professionally by highly qualified personnel.

MECHANICAL ANALYSIS BY BIELLA QUALITÀ TOTALE

Tessil Controll System entrusts some laboratory analysis to strategic partner Biella Qualità Totale.

Biella Qualità Totale with its high-tech products is able to implement and strengthen the various controls performed by Tessil Controll System with chemical and mechanical analysis, in accordance with the key fabric methodologies.

Biella Qualita’ Totale has the SINAL credentials, which guarantees the correct results, together with periodical environmental, functional, professional and material conformity verifications.

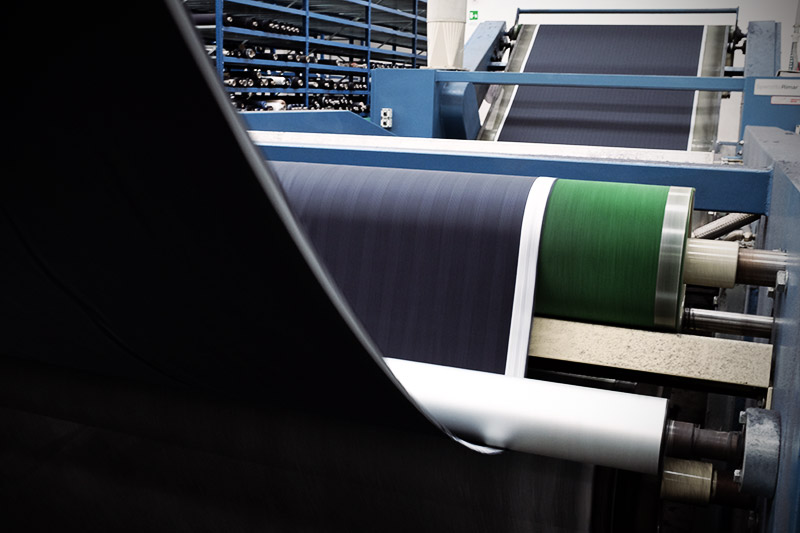

Steaming

According to the agreements between Tessil Controll System and the manufacturers, the fabrics can be subjected to an intense steaming treatment, followed by a twenty four hour rest. Steaming is a necessary process to highlight hidden problems, giving greater safety in the fabrics’ dimensions and uniformity for the production of suits with regular sizes.

Post-steaming analysis

During the rewinding on tubes or other support, the fabrics are inspected again, to make sure that the steaming process has given the desired result and that the original aspect has not been modified. Further checks include:

- length

- height

- grain lines

- weight

Labels are applied on the selvage with progressive numbers, to facilitate consultation during inventories. At the end if this operation, the Tessil Controll System technicians attach to every bolt a computerized report, which shows all the information gathered during the test.

Washing and drying test

On request by client, controls are affected using methods indicated by the client (washing time/drying, temperature, detergents to be used).

Packaging

When all controls are finished, the bolts are packed for delivery, labelled and sealed automatically. Every phase is organized according to the clients’ preference: from personalised forms to the choice of boxes used or other packaging, to the choice of the forwarder.

Delivery and logistics

Tessil Controll System takes care of organising the flow of the fabrics according to the clients’ specific request: entire delivery or divided into various lenghts and delivered to different clients all over the world. Tessil Controll System offers its clients a Storage service which allows them to organise efficient deliveries while keeping cost down. The Warehouse is automatically controlled daily, allowing monitoring in real time.